It is important to have a way to relate the tangential component of the. To the speed of the worm gear NG in rpm.

View Design of Worm Gearpdf from ME MISC at VIT University Vellore.

. Check spur gears strength 4. ØD 1 25 50 L L S 10 ØD ØPD. Name That Gear What type of worm gear set is this.

Design shapes of spur gears 3. Gears Engineering and Design. The procedure was proven to be safe and reliable in rating the load capacity and useful in the design of worm gear drives with compact size and high power transmission.

There are no great advances in gear technology described. Gear Acetal Insert Brass SPECIFICATIONS. Select number of teeth on worm.

Worm gears are used to transmit power between two non-intersecting non-parallel shafts. Running a worm gear set with the gear worm wheel as the input member is corn-monly caUed back driving Back drive effi-ciency of a worm gear set is lower than its forward drive efficiency. The efficiency of a worm gear ranges from 98 for the lowest ratios to 20 for the highest ratios.

Machine Design II Module 2-GEARS Lecture 16 WORM GEARS WORKED OUT PROBLEMS Contents. It does not cover helical gears used as wormgears. 13 GearsGeneral Chapter Outline 13-1 Types of Gears 13-2 Nomenclature 13-3 Conjugate Action 13-4 Involute Properties 13-5 Fundamentals 13-6 Contact Ratio 13-7 Interference 13-8 The Forming of Gear Teeth 13-9 Straight Bevel Gears 13-10 Parallel Helical Gears 13-11 Worm Gears 13-12 Tooth Systems 13-13 Gear Trains 13-14 Force AnalysisSpur Gearing 13-15 Force.

N w N G. Flowchart for worm gear designing process. The worm wheel teeth envelope the treads on worm which gives line contact between mating.

70 Nmm2 50 Nmm2 m. Things should be made as simple as possible but no simpler This book is an attempt to apply that principle to gear design by presenting information from a manufacturing point-of-view rather than a theoretical one. These gears are generally at right angles to each other.

But the multi- threaded enveloping feature is the curvature of the faces to. Equations for American Standard Fine Pitch Worms and Wormgears Per. Ød ØD1 35 64.

Where n Number of starts of the worm. Worms Steel Worm Gears. Mathematically velocity ratio VR.

Worms have to be hardened and ground. CHAPTER 11 Worm Gears Chapter Outline 111 Introduction 439 112 Force Analysis 446 113 AGMA Equations 449 114 Design Procedure 453 115 Conclusions 455 References 456 Further Reading 456 Nomenclature 457 Abstract Worm and wheel gears are widely used for nonparallel nonintersecting right angle gear drive system applications where a high transmission gearing. 32 Design Procedure for Selection of worm gears - Using PSG Design Data Book Manufactures Catalogue Step.

Design of peripheral structures of gears 5. GA-based optimization procedure for the design of gear. By varying design the back drive efficiency can be reduced to zero a in a self-tacking or irreversible gear setf the gear tries to drive the worm internal.

Design the worm gear if it is made of Phosphor bronze 8. Transmission power input and output speeds. The pitch line velocity is ideally up to 30 ms.

American Standard Design for Fine-pitch Worm Gearing ANSI B69-1977 This standard is intended as a design procedure for fine-pitch worms and wormgears having axes at right angles. Select the number of teeth for the pinion and the g. Clarify specifications and determine basic elements 2.

POM PA 66 Tensile strength R with 23C. We will use the term Pitch P for both the pitch in this tutorial. WORM GEARS WORMS MODULE 1 WORMS RIGHT- AND LEFT-HAND WORM GEARS RIGHT-HAND 20 PRESSURE ANGLE MATERIAL.

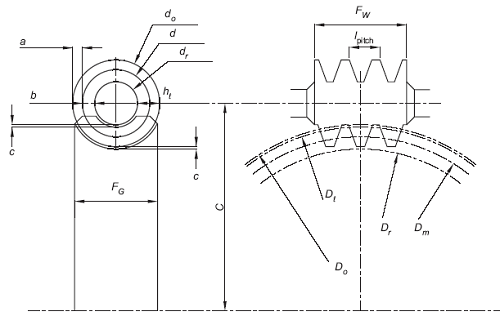

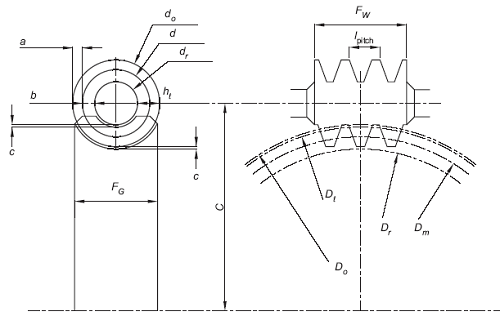

Worm gear design parameters. 1 Single-enveloping single threaded 2 Single-enveloping multi-threaded 3 Double enveloping single threaded worm gear 4 Double enveloping We really didnt discuss this so I think its not testable. Plastic worm gears are suitable for 50 torque of bronze worm gears.

PDF In worm gear mechanism power loss is one of the critical issues which requires attention from gear designers and researchers. We know that linear velocity of the worm vW l. To prevent the worm gear from driving the worm refer to clause 9 of 6034-B92 for a discussion of self-locking in the static condition.

Martin worm gear sets under no condition should be considered to hold a load when at rest. The axial pitch of the worm and the circular pitch of the gear must be same for a mating worm and gear. A worm gear drive is used to transmit 22 kW between two shafts which are 225 mm apart.

Strength of Gear Teeth P N RAO 16 Gear. Worm gears provide a normal single reduction range of 51 to 75-1. Is outlined as follows.

Provisional spur gear selection procedure for a given. Plastic worm gears Plastic worm gears are suitable for low sliding speeds 15 ms and medium tooth pressure due to their bad thermal conductivity. In this series we explain how to design gears and peripheral parts according to procedures using simple mechanisms.

Speed of the Worm N1 20 RPM. It consists of worm and worm wheel. It is the ratio of the speed of worm NW in rpm.

It covers cylindrical worms with helical threads and wormgears hobbed for fully conjugate tooth surfaces. SELF-LOCKING ABILITY There is often some confusion as to the self-locking ability of a worm and gear set. Strength of Gear Teeth contd P N RAO 17 Classes of Gears Transmitted load depends on the accuracy of the gears Gear.

Proportions of worm and worm gear 2. Executing the drawings of the parts related to the gears. To ensure that the worm gear will drive the worm fstat cosφn tanλ 1556 where values of fstat can be found in ANSIAGMA 6034-B92.

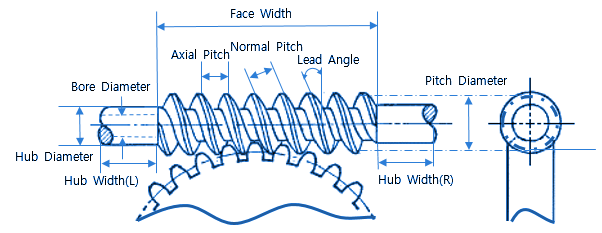

P Circular pitch of wormgear P axial pitch of the worm P x in the central plane P x Axial pitch of worm P n Normal circular pitch of worm and wormgear Px cos λ P cos ψ λ Lead angle of worm ψ Helix angle of wormgear. DESIGN PROCEDURE FOR. Now lets say we have the following design input.

Direction of Rotation and Thrust Right Hand NOTE. Let l Lead of the worm and. Transmitted Power Input and Output speed Center distance Type of driver and driven load.

Worm Gear Design The power to be transmitted The speed of the driving gear. Load sharing and stress analysis of single enveloping worm gearing considering transmission errors. The transmission ratio is 241.

Worms are run with bronze gears at high speeds the worm is usually hardened with ground threads. Specify the Lewis form factor for worm gear teeth from Table 10-4 page482 Pdf 498 4 5. Thread Data 3148 3 35 6333 7 11 Single Thread Double Thread Lead Lead Angle Ø135 S ØPD.

Also the module of the worm as well as the gear must be equal for a mating worm and gear. The design procedure of the worm gear follows the AGMA standard 6. Sn 5 88 ksi 44 ksi Table 12-1 Y 421 Fs 44000 1 421 8 Fs 2316 lb Use F s 1900 lb for design purposes.

Introduction to Gear Design Introduction Albert Einstein once said. DG Pitch circle diameter of the worm gear. The worm is threaded screw and worm wheel is toothed gear.

Worm Gear Calculation And Design Mitcalc 12 Youtube

Detorima Worm Gear Design Calculation Pdf Docker Image Docker Hub

Agma Worm And Spur Gear Design Equations And Calculators

Pdf Machine Design Ii Module 2 Gears Lecture 16 Worm Gears Worked Out Problems Contents Aju Joseph Academia Edu

Worm Gearing Classes Proportions Materials And Worm Gear Cutting

0 comments

Post a Comment